Diverter Valves, Slide Gates, and Rotary Airlocks

Flo-Dynamics supplies a wide variety of slide gate valves, airlocks, and diverter valves. Applications include all types of dry solid processes and associated industries.

Slide Gate Valves

Slide gates are designed to stop, start, or meter the flow of dry solids. We can supply valves for any conveying application such as food, pharma, aggregates, minerals, chemical, and plastics.

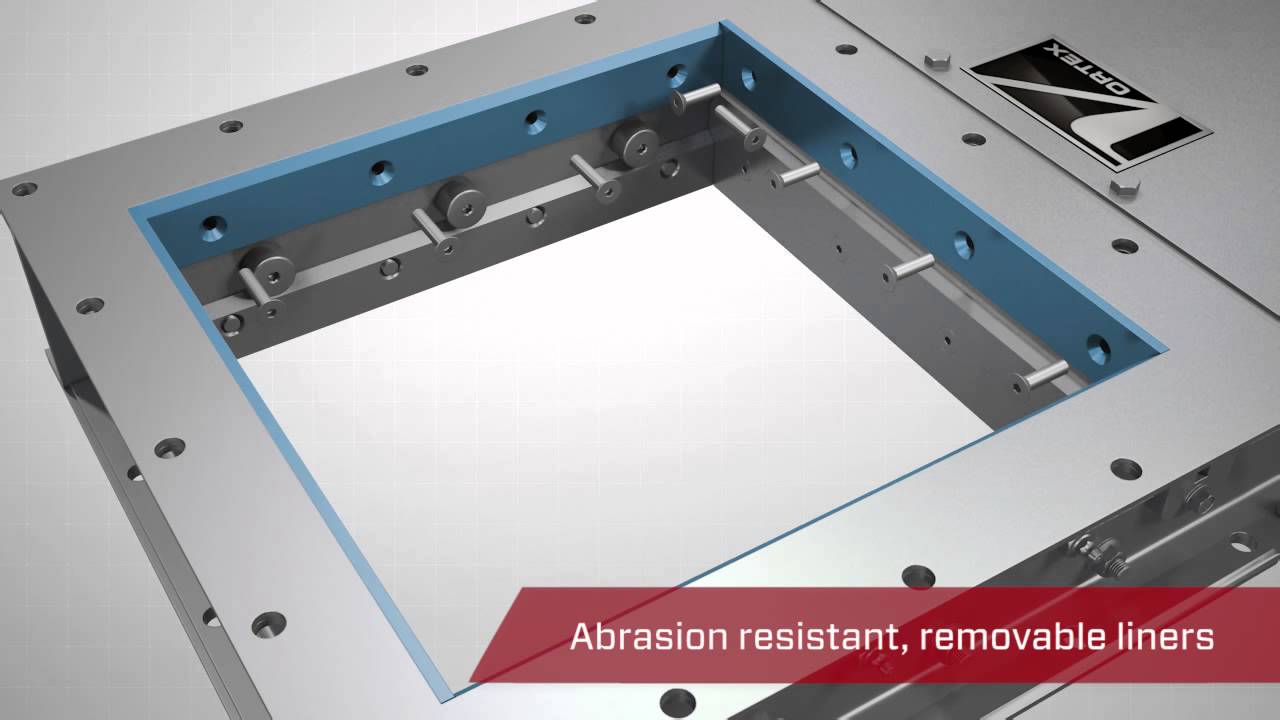

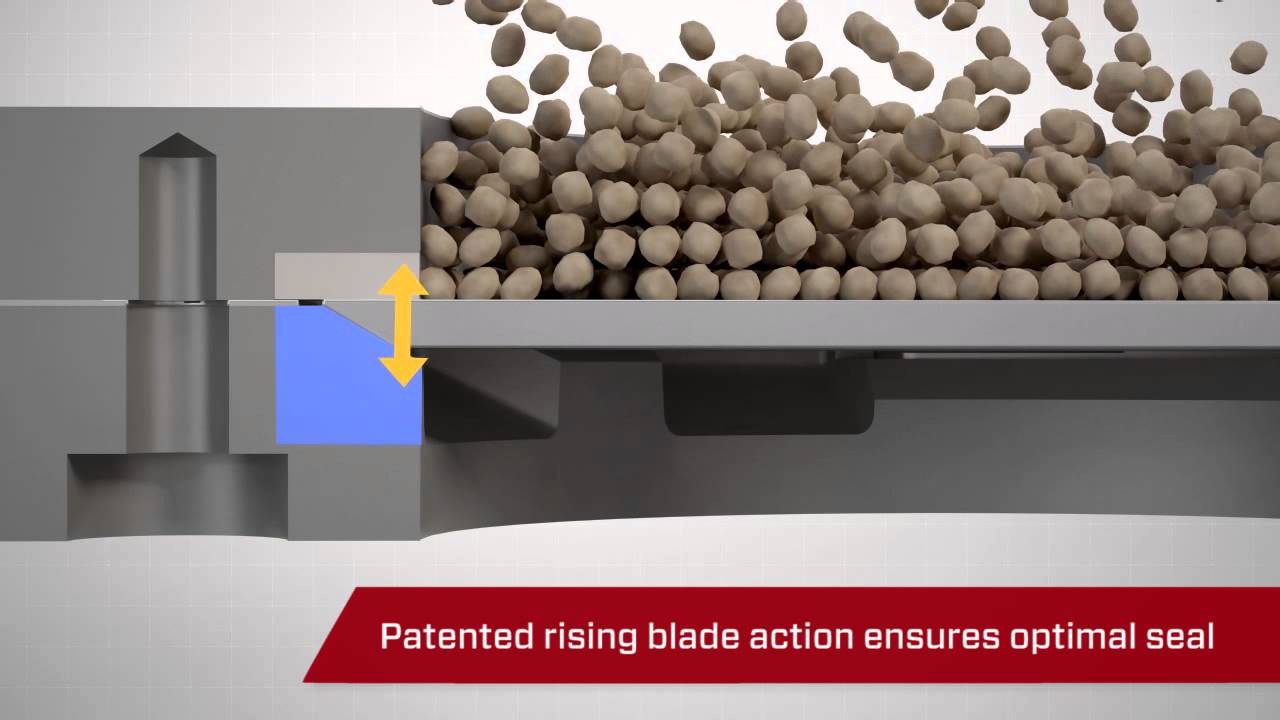

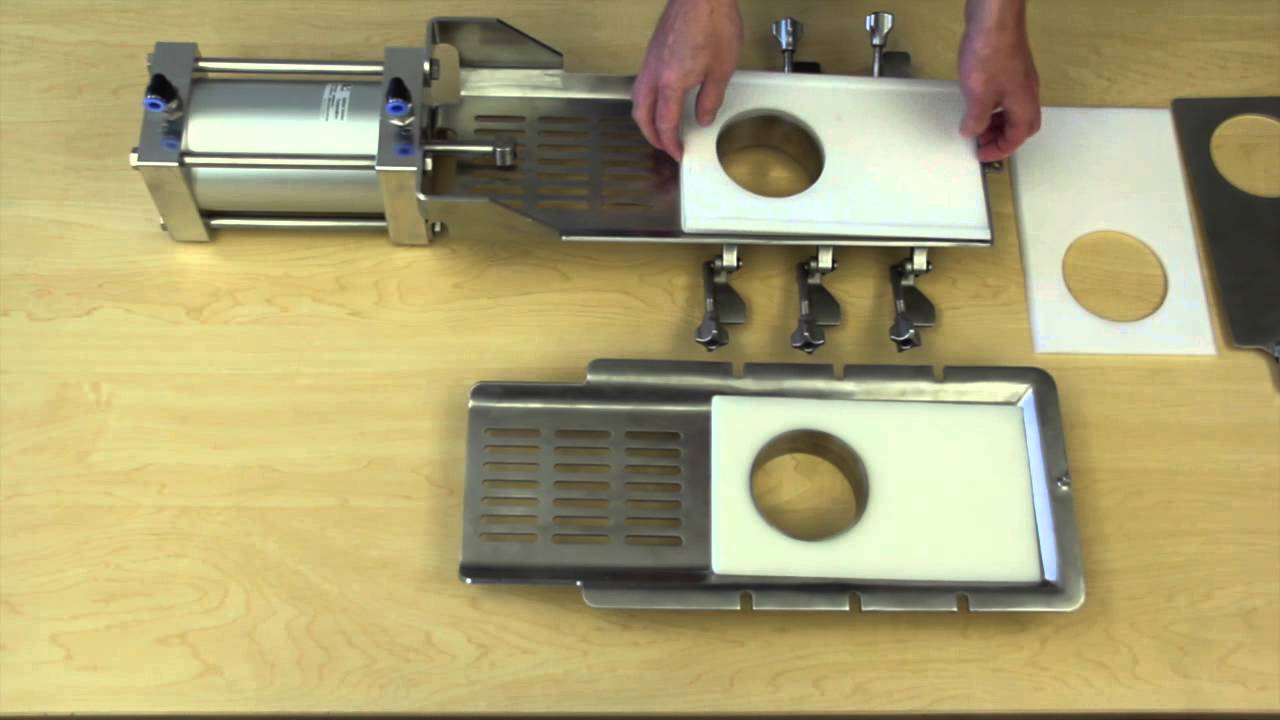

Slide Gates

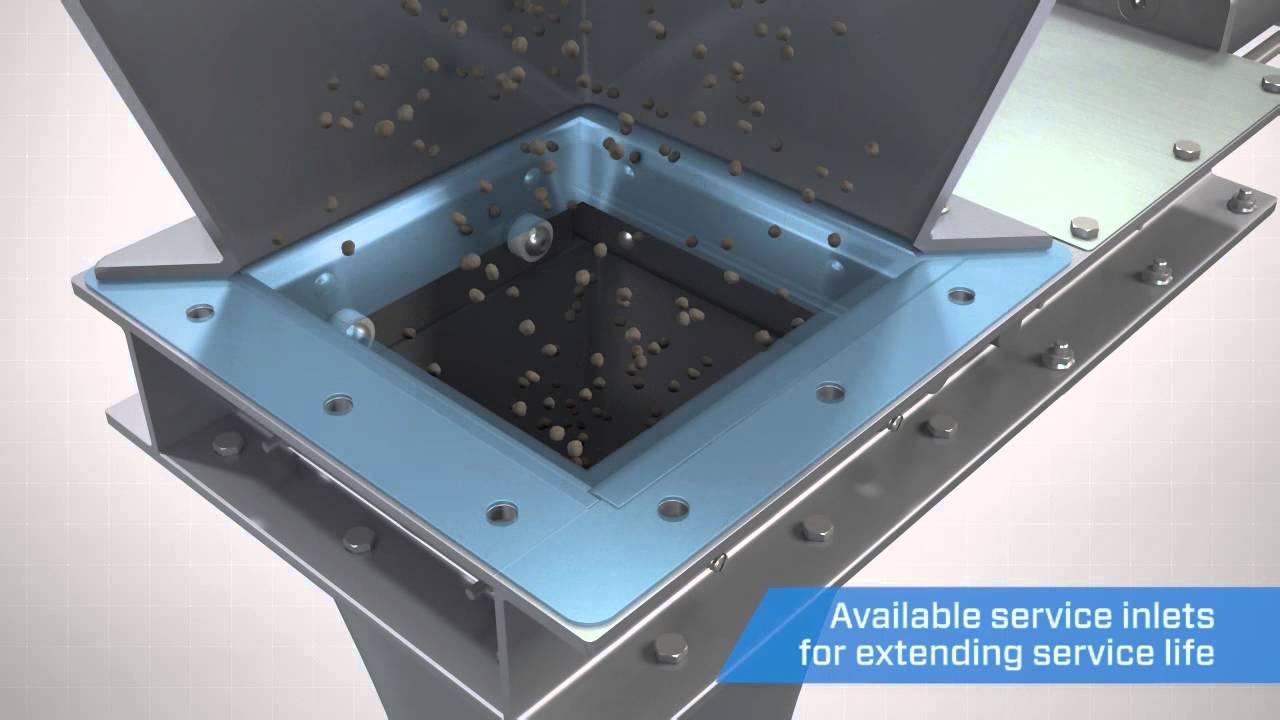

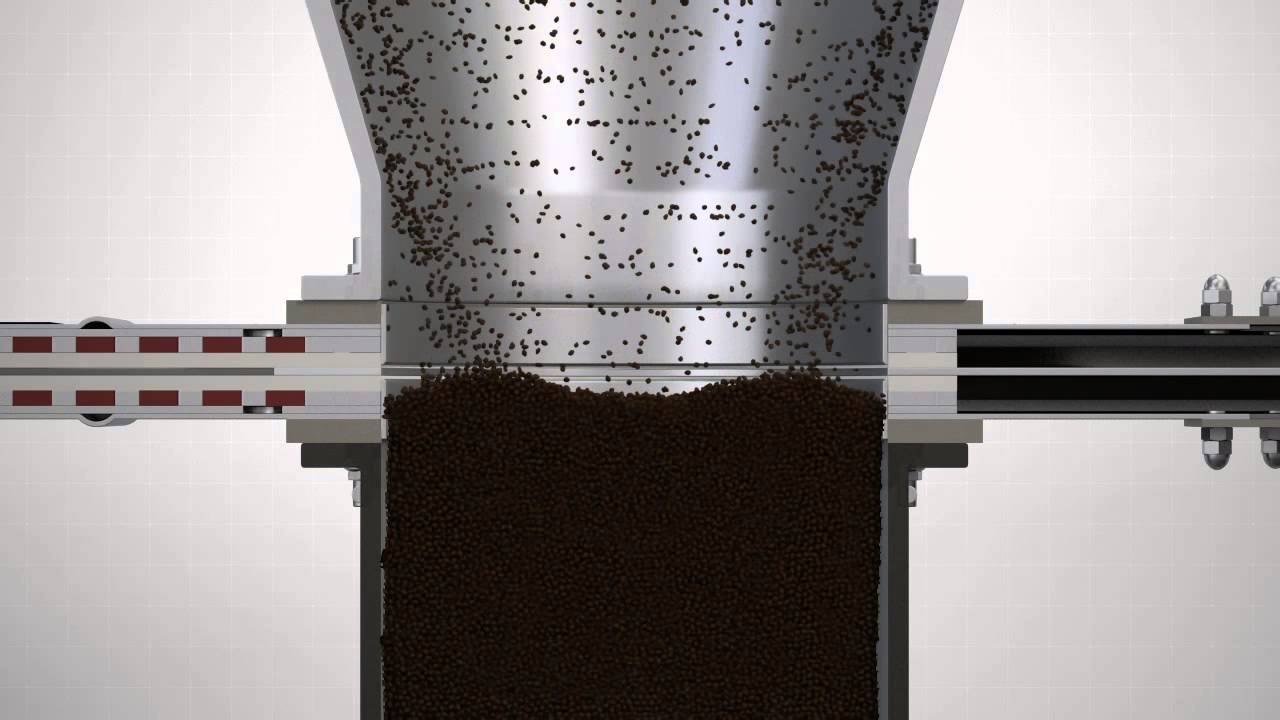

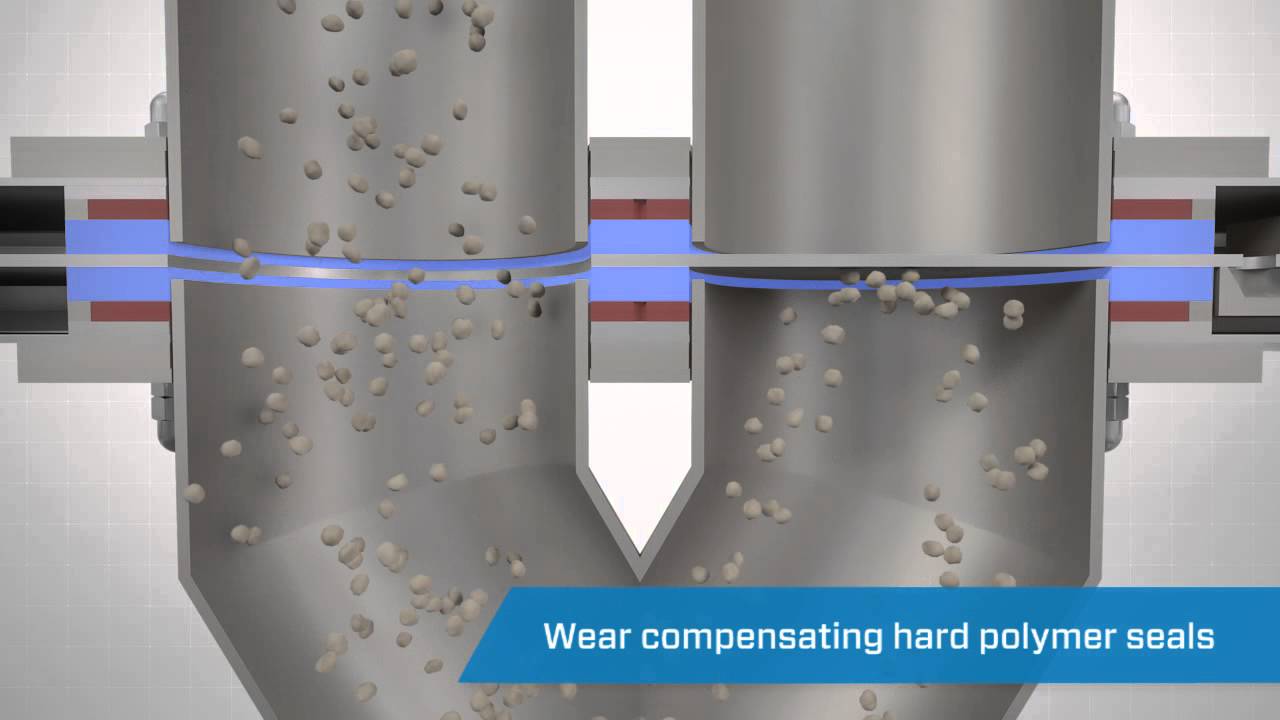

Ideal for controlling dry bulk material in gravity flow, dilute phase or dense phase pneumatic conveying applications. Vortex slide gates are designed and engineered with two main principals in mind: 1. Extend the service life of the valve and 2. Perform maintenance without taking the valve out of line. Conventional knife gates and butterfly valves were commonly used in dry bulk solid material handling systems. Though knife gates and butterfly valves are well-designed for handling liquids and gases, they are ill-equipped for handling dry bulk solids.

Iris Valves

The patented Vortex® Iris Valve is designed specifically to handle dry bulk solids in gravity discharge of free-flowing material from bins, bulk bags, chutes, and hoppers. The Vortex Iris Valve is designed with stainless steel control rings, metal handle and trigger lock, and nylon shim for durability and smooth actuation. A form fitted fabric sleeve provides a dust tight seal and product barrier, which prevents material leakage into the atmosphere.

Titan Heavy Duty Gates

The Vortex Titan Series Maintenance Gate is designed for use in gravity flow applications handling heavy duty and/or abrasive dry materials. Its purpose is to shut off material from a hopper or silo when maintenance of downstream equipment is required, or if an upset condition occurs. In the open position, the gate can seal slight aeration.

Diverter Valves

Diverter valves will divert bulk materials from a single stream to multiple streams, or converge materials from multiple streams to a single stream in gravity flow, dilute phase or dense phase pneumatic conveying applications. Flo-Dynamics can supply standard or custom engineered valves a wide range of applications serving many industries including chemical, cement, coal, food, frac sand, grain, minerals, petrochemical, pharmaceutical, plastics, polymer, rubber and mining.

Gravity Diverters

Gravity flow applications where dry bulk solid materials must be diverted from one source toward up to three destinations. Suitable for non-abrasive to abrasive powders, pellets and granules. Modifications available for handling corrosive materials and/or for wash-down environments.

Pneumatic Diverters

Diverting or converging materials in high cycle applications. Common in storage fill and/or storage transfer applications. When applied in minimally abrasive applications or as an air directional valve, Wye Line Diverters often record more than 10 million cycles over the course of their service life.

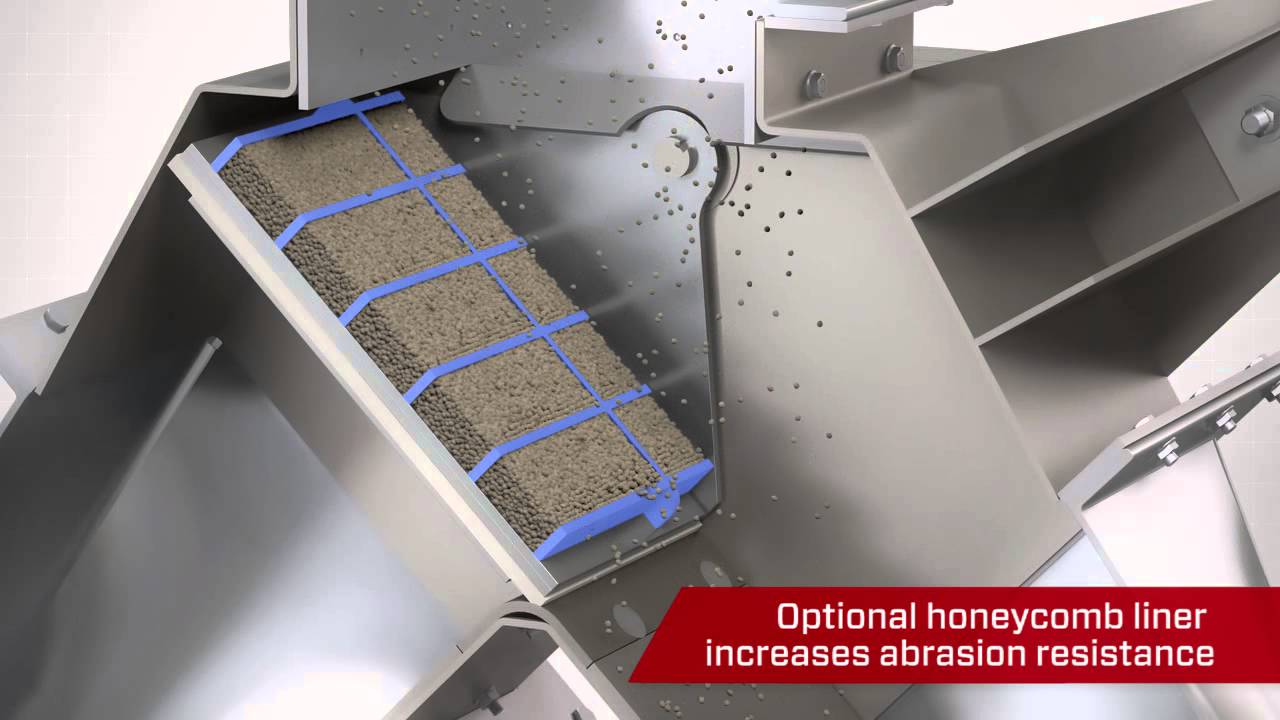

Titan Heavy Duty Diverters

Used to divert heavy-duty and/or abrasive dry bulk solid materials from one source toward two or three destinations in gravity-fed applications. The Vortex® Titan Lined Diverter™ offers in-line maintenance features, durable materials of construction, reduced downtime, prolonged service life and many other significant advantages over alternative flap diverters.

Loading Spouts

Loading Spouts can be supplied for stationary or variable position filling applications. They provide fast and steady material flow during the loading of dry/bulk solid materials in open and/or enclosed vessels such as trucks, railcars, tank vehicles, ships, barges, and stockpiling. These loading spouts are designed to capture fugitive dust, prevent material waste, and ensure plant and environmental safety, with low maintenance and service expenses.

Loading Spouts

Vortex® Loading Solutions provide fast and steady material flow during the loading of dry/bulk solid materials in open and/or enclosed vessels such as trucks, railcars, tank vehicles, ships, barges, and stockpiling. These loading spouts are designed to capture fugitive dust, prevent material waste, and ensure plant and environmental safety, with low maintenance and service expenses. From the retractable loading spout attached to the bottom of a silo/hopper or located at the end of an air conveying system, to the dust collecting filter system, to the loading spout positioner, Vortex Loading Solutions offer a complete line of versatile loading spout systems for your loading process.

Spout Positioners

Vortex® Spout Positioners are designed so that materials pass through a fixed inlet. Above, a traversing hopper slides across a fixed support pan. A loading spout is attached beneath the traversing hopper to allow exact positioning of the spout above a truck or railcar waiting below. Loading spout positioners are made out of steel and can be designed and manufactured to meet your individual project specifications to handle almost any flow rate and travel distance.

Spout Filtration

Vortex dustless spout filtration systems are engineered to capture the fugitive dust emitted from the spouts and deposit it back into the material flow during the loading process, eliminating material loss. These filter systems are more cost-effective than a free-standing dust collection system, which often requires the installation of additional ductwork, discharge airlock and some way to reintroduce the material back into the system. These very compact filter systems are used in conjunction with standard volume loading spouts in enclosed, open, or combination loading applications. They feature a unique square-shaped design, which allows for a more low profile and compact model.

Rotary Airlocks

Rotary airlocks and feeders are designed for metering materials in gravity or applications with pressure differentials. They are available in standard duty, heavy duty, highly abrasive, quick clean, and sanitary applications.

Pellet and Powder

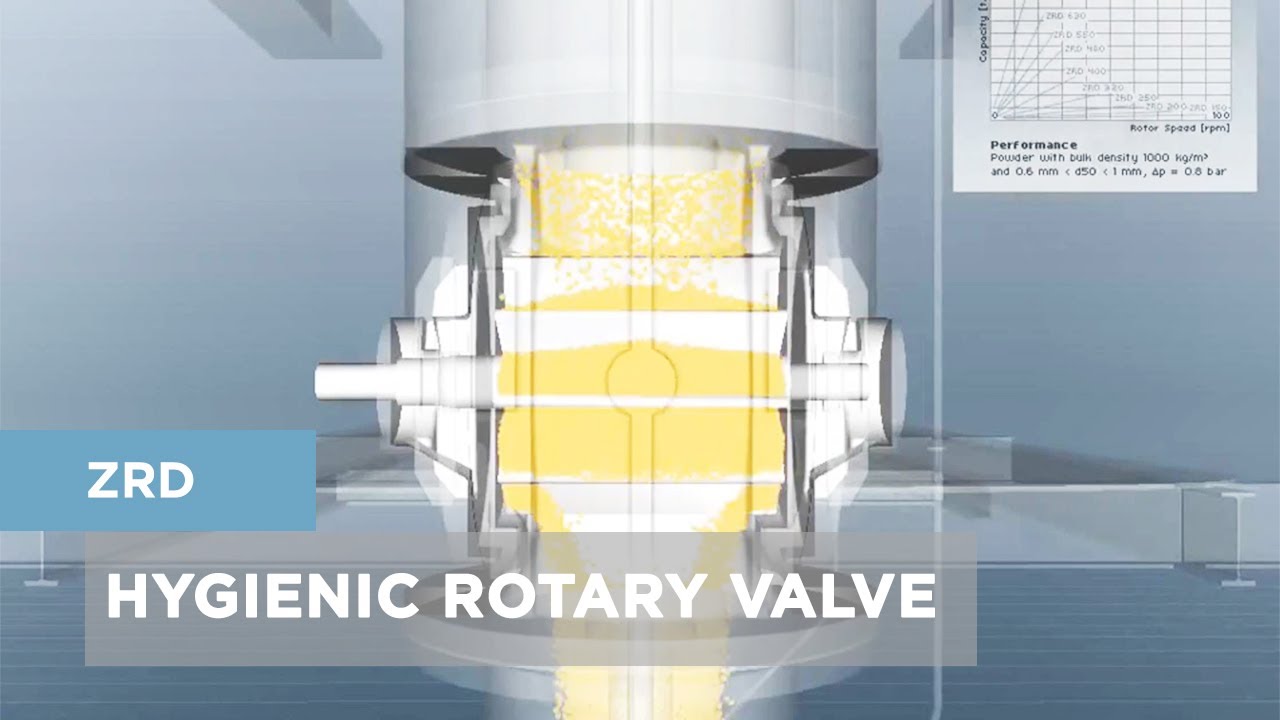

Our rotary valves are highly regarded as top-quality products in the plastics, chemical, food and minerals industries around the world.

We supply certified solutions for requirements regarding sanitary and flameproof design and ATEX conformity. Our rotary valves also set standards at high pressures and with regard to wear protection

Heavy Duty Wear Resistant

Coperion’s DUROPROTECT technology is used for wear protection in pneumatic conveying systems primarily for the cement, lime, alumina, aggregates, wood, power plants, and other heavy duty applications.

Quick Clean and Sanitary

Bulk material components for conveying and discharging food ingredients must satisfy very high demands with regard to sanitation and reliability. Coperion is the right partner for all such applications.

With our many years of experience and all-around process know-how, we are able to supply individual and efficient solutions for your production which are operationally safe, reliable, sanitary and easy to clean..

Diverter Valves, Slide Gates, and Rotary Airlock Resources

Diverter Valves, Gate Valves, and Airlock Videos

White Papers, Application Notes, & Spec Sheets

- Clear Action Gate Spec Sheet

- Coperion DWR Diverter Valve

- Coperion WET Diverter Valve

- Coperion WGV Diverter Valve

- Coperion WHK Diverter Valve

- Coperion WRK Diverter Valve

- Coperion WYK Diverter Valve

- Coperion WZK Diverter Valve

- Coperion ZFD Rotary Valve

- Coperion ZHD Rotary Valve

- Coperion ZKD Rotary Valve

- Coperion ZRD Rotary Valve

- Coperion ZVD Rotary Valve

- Coperion ZVH Rotary Valve

- Coperion ZXD Rotary Valve

- Coperion ZXQ Rotary Valve

- Coperion ZZB Rotary Valve

- Loading Spout Catalog

- Titan Maintenance Gate Data Sheet

- Vortex Aggregate Diverter

- Vortex Flex Tube Diverter

- Vortex Gravity Vee Diverter

- Vortex Handslide Gate

- Vortex HDPV2 Valve

- Vortex Iris Valve

- Vortex Maintenance Gate

- Vortex Multiport Diverter

- Vortex Orifice Slide Gate

- Vortex Pivoting Chute Diverter

- Vortex Quick Clean Slide Gate

- Vortex Roller Gate

- Vortex Seal Tite Diverter

- Vortex Temperature _ Pressure Valve

- Vortex Titan Lined Diverter

- Vortex Titan Slide Gate

- Vortex Wye Line Diverter

![Coperion Diverter Valve WYK for Powder and Pellets [Animation]](http://img.youtube.com/vi/VEWSxo4njkU/maxresdefault.jpg)