Magnetic Separation

Flo-Dynamics provides a variety of tramp metal magnets for use in food, plastics, and packaging process applications. Designs include drawer, plate, grate, and in-line magnets. We also supply heavy duty industrial overhead, permanent, and electro magnets for the recycling, construction and demolition, and aggregate industries.

Tramp Metal Magnets

Industrial Magnetics, Inc. manufactures drawer, plate, grate and in-line magnets. Tramp metal magnets are designed to remove unwanted metals from bulk solid materials, improving product quality and protect downstream equipment.

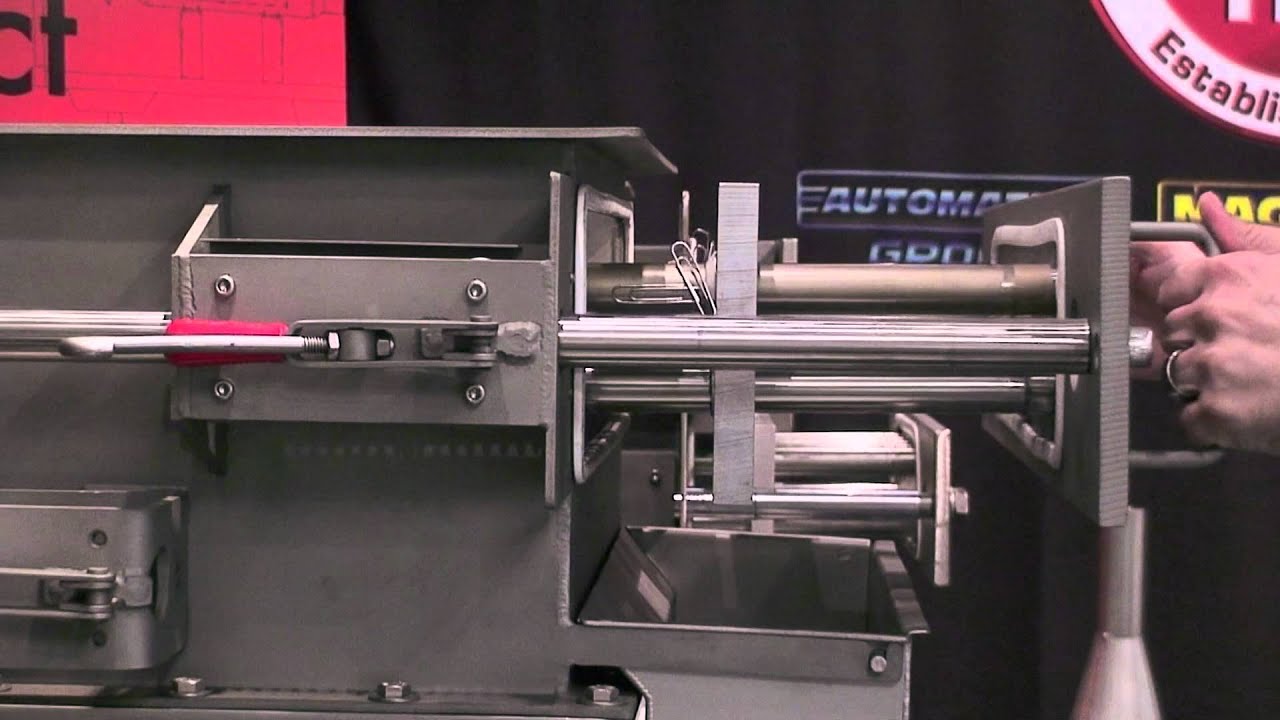

Drawer Magnets

Our Drawer-In-Housing magnetic separators consist of rows of round magnetic tubes that are assembled into drawers. The magnetic tubes of each row are aligned on alternating centers from the row directly above or below it. As product flows into the top of the housing, it is forced to cascade in a zig-zag pattern from row to row over the magnetic tubes. This ensures maximum tramp metal capture since the product comes in direct and repeated contact with a magnet as it travels through the housing. These magnets can be self-cleaning or manual clean.

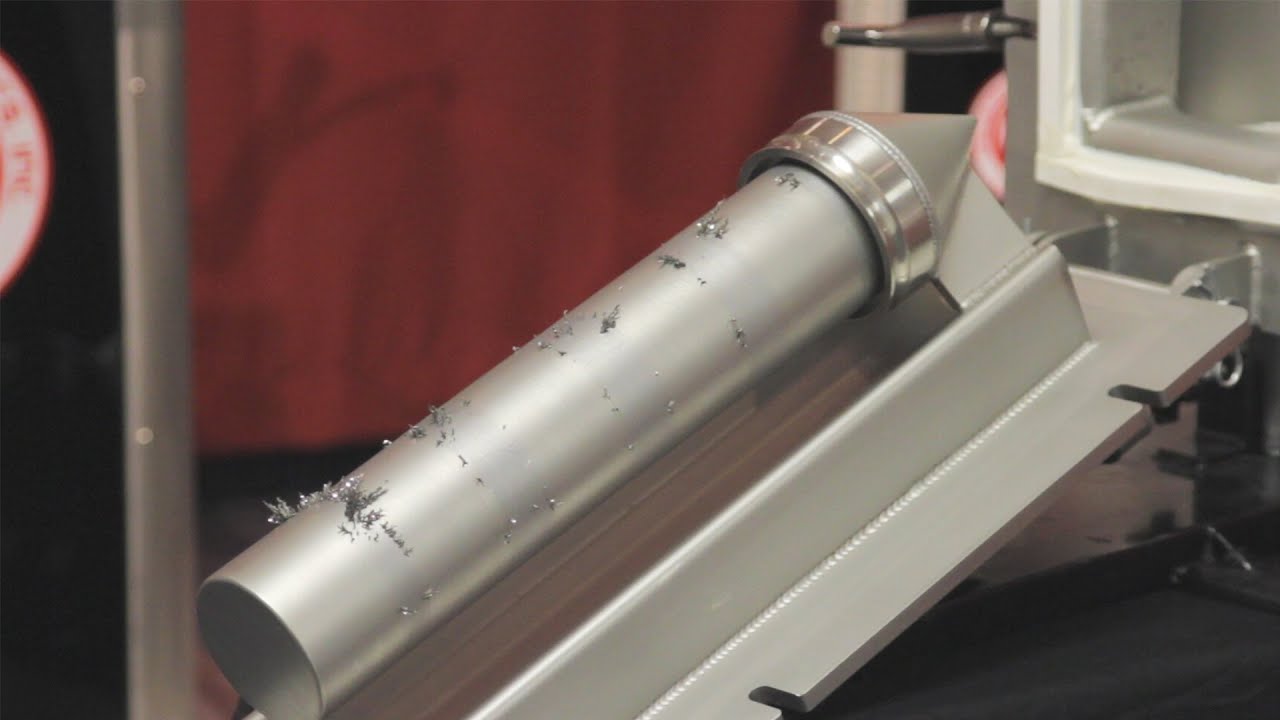

Pneumatic Line Magnets

Ideal for dilute-phase pneumatic systems, the Pneumatic Line Housing is suitable for processing dry, powder, and granular materials. It can be used ahead of processing equipment and bulk load-out stations to ensure product purity and protect machinery from tramp metal damage and is also available in a cart mounted design for portable bulk unloading. Magnets can be self cleaning or manual clean.

Plate Magnets

Plate Magnets are ideal for angled chute metal separation applications where product degradation is a concern. Take a look at our large number of plate magnets that range in size and design depending on your application. Both EZ-Clean and Self-Cleaning Magnets utilize a stripper pan cleaning mechanism that allows the collected tramp metal to be easily released. Plate magnets come in various styles such as flush face, extended pole, and spout face.

Heavy Duty Magnets

Dings Magnetics Group supplies overhead, permanent, and drum magnets for heavy duty applications. Heavy duty magnets are designed to remove unwanted metals from bulk solid materials, improving product quality and protect downstream equipment.

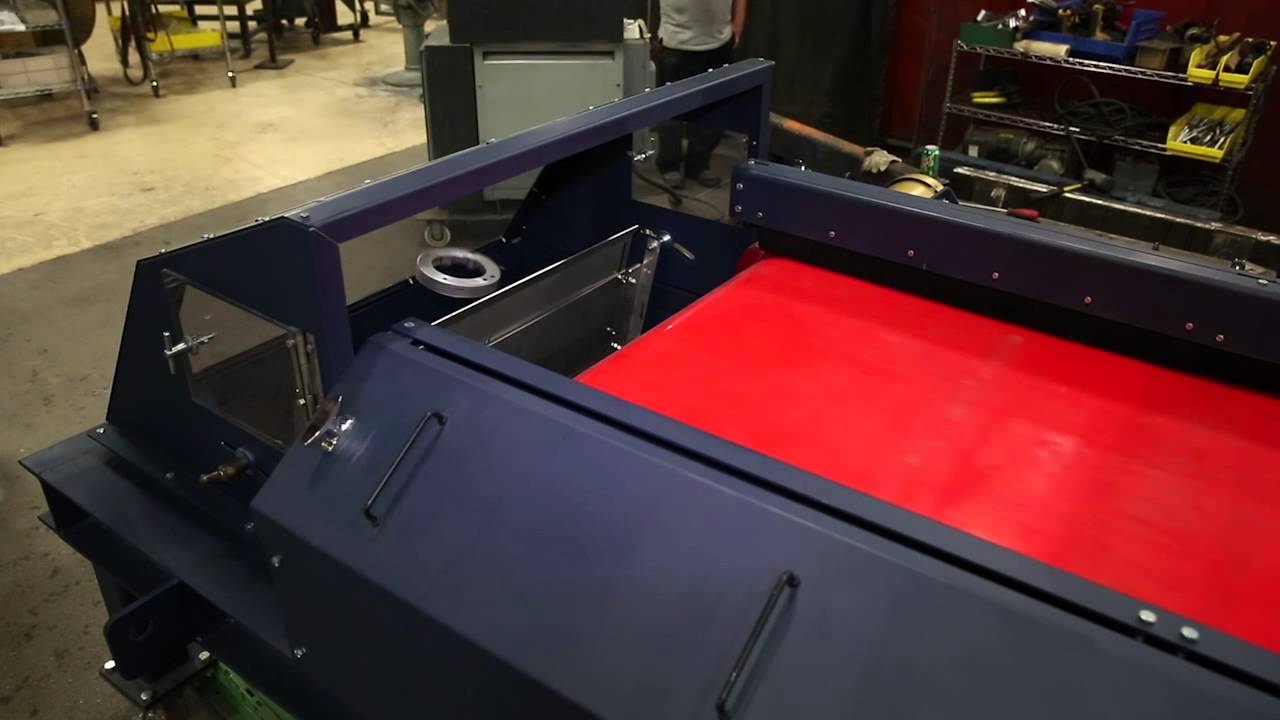

Overhead Electromagnets

Overhead Electromagnets are suspended over conveyor belts and vibratory feeders. They are designed to magnetically lift ferrous metals out of bulk material which ensures product purity and protects processing equipment. Any ferrous metal that is attracted to the magnet face is either automatically and continuously removed with our self-cleaning models or held in place on stationary models until the magnet is turned off. Our Overhead Electromagnets remove damaging ferrous tramp metal, which can cause costly repairs and downtime.

Overhead Permanent Magnets

Overhead Permanent Magnets are non-electric and are suspended over conveyor belts or vibratory feeders. No external power source is required to generate the magnetic field. Any ferrous metal that is attracted to the magnet face is either automatically and continuously removed with our self-cleaning models or held in place until manually removed with our stationary models. Our self-cleaning models are designed with a non-magnetic laser cut stainless steel frame. This prevents ferrous metal from collecting on the frame and in between the belt and magnet face.

Deep Draw Drum Magnets

Magnetic Drums can be installed inside closed chutes, at outlets of chutes and hoppers, or where materials discharge from feeders and conveyors. Drums are continuously self-cleaning. During operation, a non-magnetic shell is driven around an internal stationary magnet. Material to be separated is fed against or near the revolving stainless steel shell. The ferrous metal is magnetically drawn out of the material and held against the revolving shell. Then the ferrous is discharged at the other side of the drum, which is no longer in the magnetic field. The non-magnetic material falls away in a normal trajectory.

Advanced Detection Systems

Advanced Detection Systems’ engineering, service and sales staff are metal detector experts. We have experience working with many types of customers including aggregates, chemicals, mining, quarry, and recycling trades.

Surround Scan Protector Heavy Duty Metal Detector

Detects ferrous, non-ferrous and stainless steel tramp metal; preventing damage to processing equipment and costly downtime. Heavy duty steel construction and NEMA 4 enclosure provide long term, reliable performance in outdoor installations. Removable end plate facilitates installation on existing conveyor frames. Product monitor feature displays product and metal signals simplifying Protector HD sensitivity adjustments. AccuLearn Technology automatically adjusts sensitivity based on your specific product characteristics. Enhanced power supply ensures reliability in the presence of electrical spike, dips and radiated noise. Programmable contacts for full PLC integration and reject-device control of automated divert gates or belt plow systems. Splice sensor and metal marking accessories complete the Protector HD’s system for detecting and locating tramp metal when spliced conveyor belts are being used.

Surround Scan Protector LP (Low Profile) Heavy Duty

HD LP detects ferrous, non-ferrous and stainless steel tramp metal; preventing damage to processing equipment and costly downtime. It has a 45% smaller coil enclosure and 40% weight reduction, heavy duty steel construction and NEMA 4 enclosure providing long term, reliable performance in outdoor installations. With our patented AccuLearn Technology, it automatically adjusts sensitivity based on your specific product characteristics. Splice sensor and metal marking accessories complete the Protector LP’s system for detecting and locating tramp metal when spliced conveyor belts are being used.

SurroundScan Protector HD Ultra Metal Detector

The Protector HD Ultra provides 2x more sensitivity than a standard Protector HD. Including heavy duty steel construction with NEMA 4 electronics enclosures for long-term reliability. Our touchscreen controls make setting up and adjusting the detector quick and intuitive. Users can adjust the detector to ignore smaller non-damaging metals, while larger contaminants are detected for removal. AccuLearn Technology learns your products’ characteristics and automatically adjusts the detector’s sensitivity settings based on those characteristics, without any extra input from the operator. Adjustable RF protection ensures reliable performance in the presence of radiated noise and power fluctuations. Programmable contacts for full PLC integration and reject device control. Detects ferrous, non-ferrous and stainless steel. Product Monitor provides real time signal values of your product and specific metal contaminants that must be detected.

Magnetic Separation Resources

Metal Detection and Magnet Seperation Videos

White Papers, Application Notes, & Spec Sheets

- Deep Drawer Drum Magnets

- Drawer Magnets

- Large Tube Drawer Magnet

- Magnetic Drums

- Magnetic Head Pulley

- Magnetic Tubes

- Overhead Electromagnet

- Overhead Self Cleaning Magnets

- Overhead Self-Cleaning-Electromagnet

- Overhead Stationary Electromagnet

- Ox Drawer Magnet

- Plate Magnet

- Pneumatic In-line Magnet

- RotoDrawer Magnet

- Severe Duty Overhead Electromagnet